DELAY ANALYSIS

IS IT POSSIBLE TO SUBSTANTIATE A PROJECT DELAY WITHOUT SCHEDULES?

FORMULATION | ANALYSIS | MANAGEMENT

One of my favorite questions when teaching delay analysis is: Do you always need a project schedule to substantiate an extension of time claim? Before you make up your mind consider the following.

A critical path project schedule has become so commonplace that we can hardly imagine a project without one. Being involved in many project delay disputes I have seen my fair share of projects with schedule deficiencies. It ranges from projects where no schedules were utilized or where schedule information is no longer available to projects where the schedule is simply a list of activities.

How do we analyze a delay facing these types of constraints? None of our typical critical path delay analysis methods, like the time impact analysis, window analysis, as-planned vs-as-built analysis, etc would be of assistance because as the name suggests these methods requires a critical path method. In this article, non-critical path methods are reviewed to establish whether these methods would be sufficient to substantiate a claim for delay.

When faced with this challenging set of circumstances one of the following methods can be considered to determine the impact of a delay event.

Dr Hendrik Prinsloo is an expert witness and specialist in the analysis construction delay claims

S-Curve

The S-curve method makes use of a time-cost chart where the cumulative expenditure during the construction period is expressed. The one axis of the chart depicts project expenditure and the other project duration. To apply this method a baseline S-curve and an as-built S-curve without any additional cost are required. This method is based on the assumption that slow progress would result in a lower than planned expenditure. By comparing the baseline S-curve with the as- built S-curve the impact of the delay can be determined.

Global Impact

When applying the global impact method the duration of all the project delays is taken into account. The duration of the global (total) delay is determined by calculating the sum of the individual delays. The main problem with this technique is that the effect of concurrent and overlapping delays is not taken into account.

Net Impact

The net impact method addresses some of the inadequacies of the global impact method. The first step of the net impact method is to depict all delays as activities on a schedule. Overlaps and concurrent delays are eliminated and the net impact of the delays is calculated.

These methods might be useful in some circumstances but a superior method in my opinion is to focus on the cause and effect of the delay.

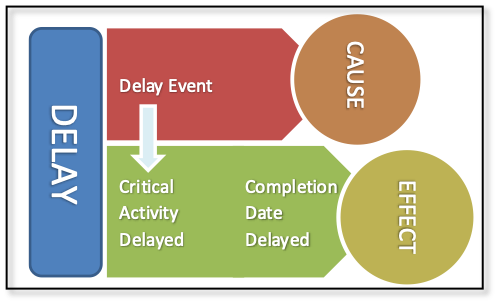

Cause and Effect

When a cause and effect approach is followed the aim is to determine what the effect (impact on the completion date) of a specific cause (the delay event) is. This might be challenging without a critical path schedule but with sufficient industry experience, an expert would be able to review the type and the extent of the delay event and determine whether the delay impacted the project completion date.